Product Information

Specification

Brand : TGB

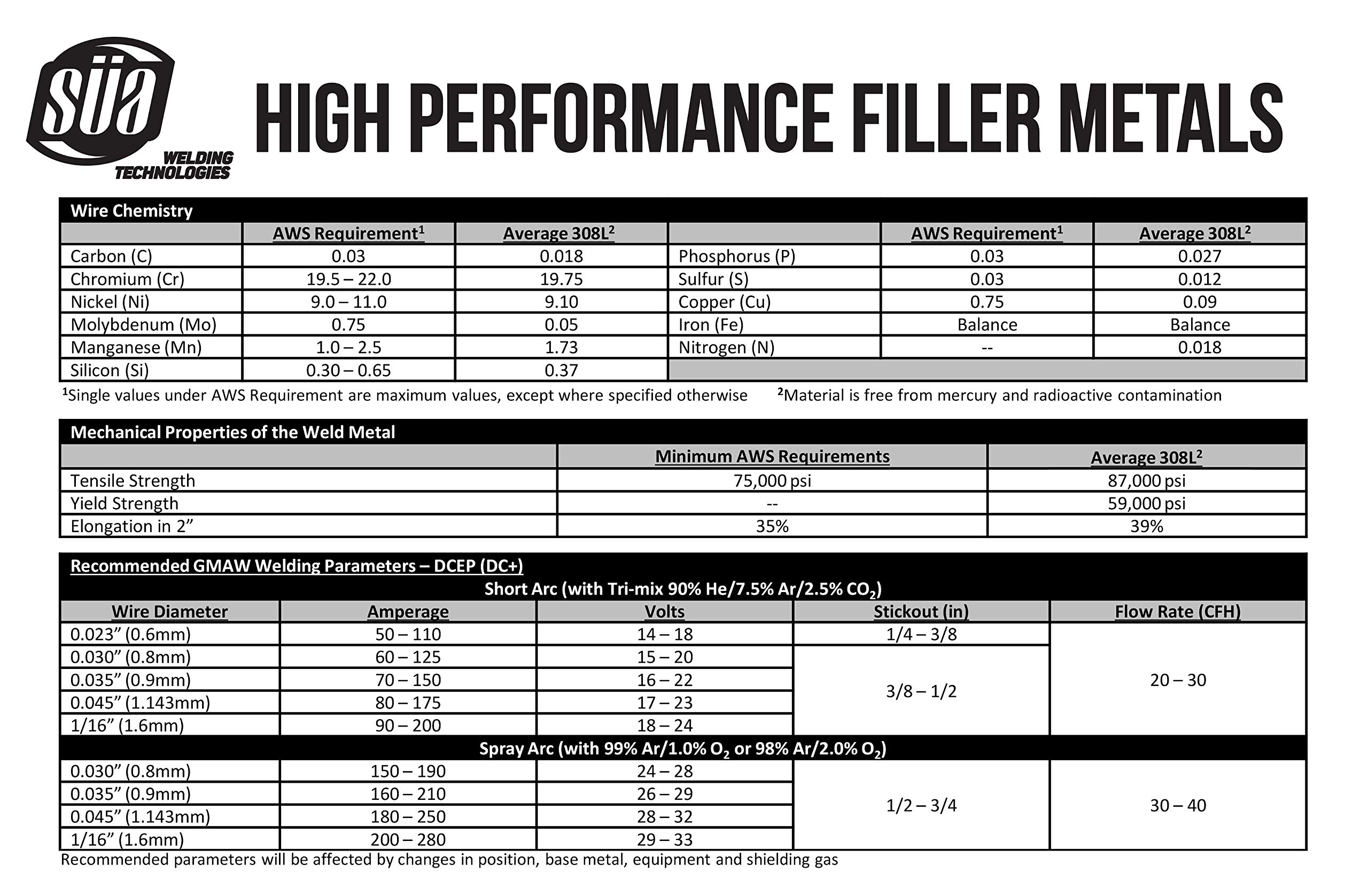

BulletPoint1 : General purpose Stainless Steel MIG Wire for welding 19% chromium – 9% nickel austenitic stainless steels such as 304L, 308 L as well as stabilized grades 321 and 350

BulletPoint2 : The maximum carbon content of less than 0.03% preserves the intergranular corrosion resistant properties of the weld deposit and weld zone, yielding x-ray quality welds

BulletPoint3 : Common applications include stainless steel fabrication of dairy, food or restaurant equipment, chemical tanks and general purpose applications where corrosion conditions are only a moderate concern; suitable for cryogenic applications

BulletPoint4 : Spool Weight: 2 Lb of Wire - Available Sizes: 0.030"and 0.035" - Spool Quantity Packs: 1 Spool, 2 Spools, 4 Spools, and 6 Spools

BulletPoint5 : For shielding gas use 100% Argon or Argon/Helium for greater penetration and higher speeds

ExternallyAssignedProductIdentifier : 7629663862256

ExternallyAssignedProductIdentifier1 : 703856605831

ExternallyAssignedProductIdentifier2 : 0703856605831

FinishType : Polished

ItemDisplayWeight : 2 pounds

ItemForm : Coil

ItemName : ER308L - MIG Stainless Steel Welding Wire - 2 Lb x 0.035"

ItemPackageDimensions_Height : 10.6934 centimeters

ItemPackageDimensions_Length : 5.207 centimeters

ItemPackageDimensions_Width : 10.5918 centimeters

ItemPackageQuantity : 1

ItemShape : Round Rod

ItemTypeKeyword : welding-wire

Manufacturer : TGB

Material : Stainless Steel

ModelName : Tig Rod

ModelNumber : 70S6

NumberOfBoxes : 1

PartNumber : 308LW2x35

ProductDescription : ER308L - Wire - MIG (GMAW) - Stainless Steel AWS A5.9 Welding Positions: All Introduction: The main component of 308L is ultra-low C-18Cr-8Ni, it is MIG wires that are widely used in welding austenitic stainless steel and it is all position welding. The weld-ability is good. Feeding wire smoothly will enable stable arc, excellent welding performance and spatter is very low. Ferrite in the deposited metal enables excellent corrosion-resistance and crack-resistance. Uses: It is widely used in petrochemical, pressure vessel, food processing machinery, medical equipment, chemical fertilizer equipment, textile machinery, nuclear reactor such as 022Cr19Ni10 (SUS 304L) and other materials of welding. Chemical Composition (%): Chemical Composition C Mn Si Cr Ni Requirement ≦0.030 1.00~2.50 0.30~0.65 19.50~22.00 9.00~11.00 Typical test result 0.023 1.63 0.40 20.12 10.35 Chemical Composition Mo P S Cu Requirement ≦0.75 ≦0.030 ≦0.030 ≦0.75 Typical test result 0.37 0.37 0.37 0.37 Welding Parameters (DC+): Diameter (mm) Φ0.8 Φ1.0 Φ1.2 Welding Current (Amps) 70~150 100~200 140~220 Notes: 1. Shield gas: Must ensure not to operate with impurity shield Gas, Recommended Rate of mixed gas: Ar + 1-3% O2. 2. Operation flow rate of shield gas: 20-25L/min. 3. Electrode extension: 15-25mm 4. The welding should be operated in clean surface without rust, moist, oil contamination and dust. 5. To avoid bubbles protect from wind its speed reach 1.5 m/s. The above parameters are for reference purpose and depend on diverse factors. Run tests, evaluate and set your welding parameters before starting the welding job.

ProductSiteLaunchDate : 2017-01-25T21:56:20.197Z

Size : 0.035" - (1 Spool)

SpecificUsesForProduct : Less spatter and good weld formation.

Style : 2lb*1PC*.030"

SupplierDeclaredDgHzRegulation : not_applicable

UnitCount : 160

UnspscCode : 23271800