Product Information

Specification

Brand : Aitoserlea

BulletPoint1 : Metal powder spray gun (oxyacetylene flame self-fluxing alloy powder spray torch) is a high temperature generated by the combustion of oxyacetylene flame, and the workpiece which has been subjected to surface degreasing and rust cleaning in advance, using oxyacetylene

BulletPoint2 : The flame is heated to 300-400℃, and then the spray tip is sprayed from the surface of the workpiece to 120-150mm

BulletPoint3 : The self-fluxing alloy powder is evenly sprayed on the surface of the workpiece through the oxyacetylene flame, and then flame-melted to the surface after specular reflection

BulletPoint4 : The molten position is moved so that the alloy powder and the workpiece base material are mutually dissolved, mutually diffused, and mutually infiltrated to form a dense and firm metallurgical bonding layer

BulletPoint5 : If a variety of different alloy powders are used, the reinforced surface layer can be achieved with different properties such as abrasion resistance, corrosion resistance, high temperature resistance and impact resistance

Color : Assorted Color

ExternallyAssignedProductIdentifier1 : 0749771659887

ExternallyAssignedProductIdentifier2 : 749771659887

FinishType : Finish

IncludedComponents : Welding Torch

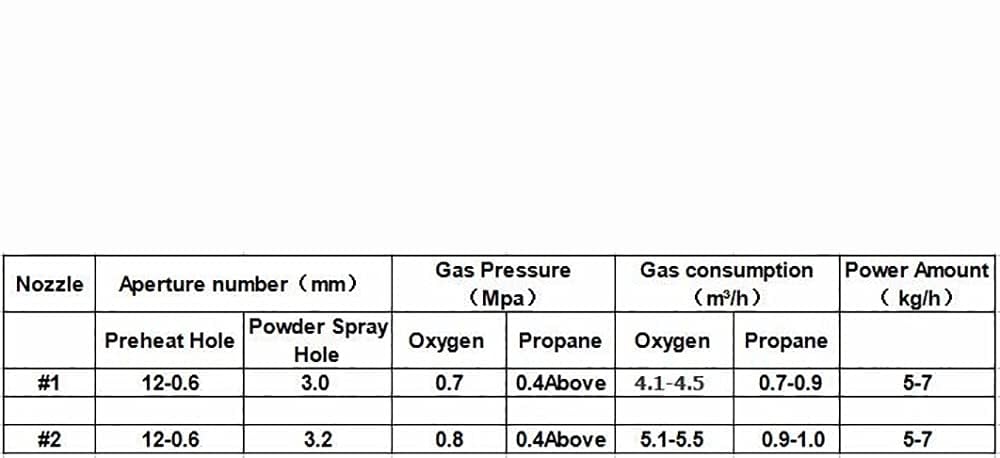

ItemName : Metal Powder Spray Welding Torch Oxygen Propane Flame Welding Gun QHT-7/h (with Propane)

ItemPackageDimensions_Height : 2.76 inches

ItemPackageDimensions_Length : 16.54 inches

ItemPackageDimensions_Width : 9.06 inches

ItemPackageQuantity : 1

ItemTypeKeyword : soldering-torches

Manufacturer : top-tool

Material : with Propane

ModelName : Welding Torch

ModelNumber : QHT-7/h

NumberOfItems : 1

PartNumber : NDNCZDHCgiam57cxhp

PowerSourceType : Other

ProductDescription : Metal Powder Spray Welding Torch Oxygen Propane Flame Welding Gun QHT-7/h Description: Metal powder spray gun (oxyacetylene flame self-fluxing alloy powder spray torch) is a high temperature generated by the combustion of oxyacetylene flame, and the workpiece which has been subjected to surface degreasing and rust cleaning in advance, using oxyacetylene The flame is heated to 300-400℃, and then the spray tip is sprayed from the surface of the workpiece to 120-150mm The self-fluxing alloy powder is evenly sprayed on the surface of the workpiece through the oxyacetylene flame, and then flame-melted to the surface after specular reflection The molten position is moved so that the alloy powder and the workpiece base material are mutually dissolved, mutually diffused, and mutually infiltrated to form a dense and firm metallurgical bonding layer If a variety of different alloy powders are used, the reinforced surface layer can be achieved with different properties such as abrasion resistance, corrosion resistance, high temperature resistance and impact resistance

ProductSiteLaunchDate : 2023-08-02T11:00:42.333Z

Size : 41X22cm

Style : centimeter

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

UnitCount : 1

Voltage : 754 volts