Product Information

Specification

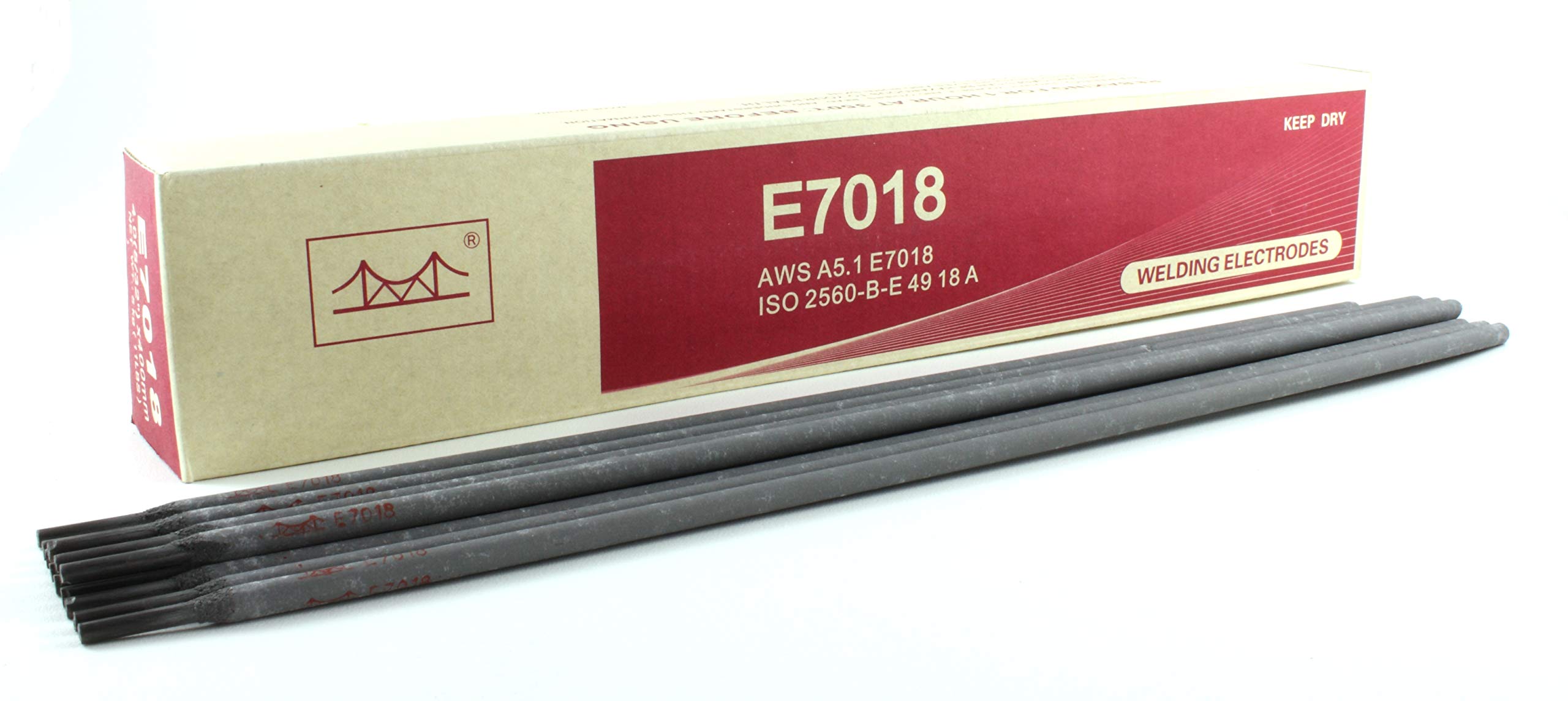

Brand : SÜA

BulletPoint1 : A low-hydrogen, all-position electrode for welding carbon steel, high-tensile steel, low alloy steel and free-machining steels - AWS/SFA 5.1 E7018 - AC/DC+ (Reverse Polarity)

BulletPoint10 : 10. Treatment before painting or dispensing.

BulletPoint2 : Quiet steady arc, low spatter, superb re-striking capabilities and high deposition efficiency all made possible by the special low-hydrogen iron powder coating and graphite tip

BulletPoint3 : Easily removable slag reveals a finely rippled bead appearance and an x-ray quality weld deposit with excellent charpy impact values at sub-zero temperatures (78 ft-lbs at -20°F)

BulletPoint4 : Typical applications include structural and fabrication steels such as I-beams, angles, plates, channels, cast steels, cold rolled steel, process piping steels and shipbuilding steels

BulletPoint5 : Select your Electrode Diameter and Package Quantity from the Options - Check Picture #3 for Welding Parameters.

BulletPoint6 : 6. Shoe glue pretreatment: improve the adhesion to prevent shoes from degumming.

BulletPoint7 : 7. Pretreatment of pasting box and glue spraying.

BulletPoint8 : 8. PCB printing pretreatment.

BulletPoint9 : 9. Silk screen pretreatment.

Color : Multicolored

ExternallyAssignedProductIdentifier : 00840338564139

ExternallyAssignedProductIdentifier1 : 0197771298108

ExternallyAssignedProductIdentifier2 : 197771298108

IncludedComponents1 : Plasma body

IncludedComponents2 : Instructions

ItemDisplayWeight : 11 pounds

ItemName : E7018 - Low Hydrogen/High Tensile - Welding Electrode/Rod - 16" x 5/32" (11 LB)

ItemTypeKeyword : arc-welding-stick-electrodes

Manufacturer : MUNDAKA TECHNOLOGIES INC

Material : Iron

ModelName : One size

ModelNumber : E7018

PartNumber : SWT-7018E16x532x11

PowerSourceType : ac

ProductDescription : Instructions: Use this electrode with DC+ (reverse polarity), however, an AC machine with sufficient open circuit voltage may be used. Clean the weld zone of all contaminants. Bevel thick sections to a 60° Vee and preheat at 300-500°F. Set amperage to the proper range as listed on the product recommended amperage chart. Maintain a short arc length and hold the electrode at a 15° angle into the direction of travel. Weaving technique is preferred, however, do not exceed 3 times the diameter of the electrode. Do not use the whipping technique as this will cause porosity in the weld deposit. Always allow high-carbon steels to cool slowly before removing the slag.

ProductDescription1 : It can be used in automobile production, printing, pasting box, dispensing, painting, glue, silk screen,

ProductDescription2 : In sealing and other industries, there is no limit to materials. All kinds of materials can be processed to increase dyne value,do not damage materials.

ProductSiteLaunchDate : 2023-10-17T18:40:01.946Z

Size : 5/32" - (11 Lb)

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

UnitCount : 1

UnspscCode : 23271800

Voltage : 220 volts_of_alternating_current

Wattage : 220 watts