Product Information

Specification

Brand : WYDDDARY

BulletPoint1 : DUAL MOTOR: The vibrating sieve use dual motor material propulsion technology, faster discharge, more fine screening, can work continuously for 8-9 hours

BulletPoint2 : LARGE FEED PORT: 16.14*11.81" feed port, can be put into a one-time around 33.1LBS (15 kg) of material

BulletPoint3 : TWO-STAGE OUTLET: With two stage outlet, the classification of materials can be automatically excluded, saving time and labor

BulletPoint4 : SHOCK ABSORPTION SEAL STRIP: The stainless steel pressure strip contains silicon rubber shock absorption seal strip. Silicone seal to prevent material leakage. With a certain degree of flexibility, reduce the friction when working, less noise

BulletPoint5 : WIDELY APPLICATION: Linear sifter is widely used in chemical industry, plastics, metallurgy, glass, building materials, fertilizer, ceramics and other industries

ExternallyAssignedProductIdentifier1 : 0198462079242

ExternallyAssignedProductIdentifier2 : 198462079242

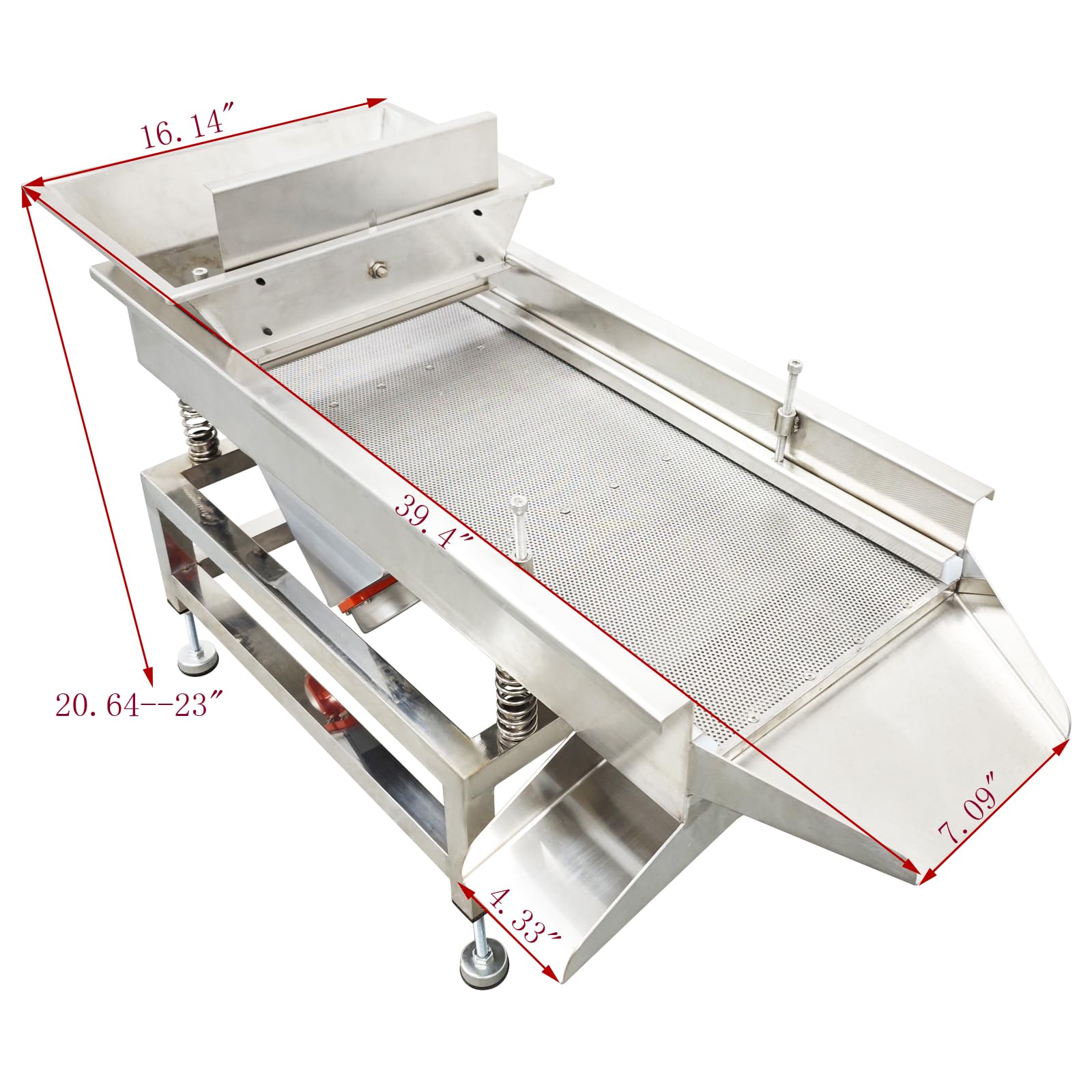

ItemName : WYDDDARY Stainless Steel Linear Vibrating Screen Dual Motor Linear Sifter Machine (2mm Round Hole Mesh) 110V TB608

ItemPackageDimensions_Height : 20.28 inches

ItemPackageDimensions_Length : 41.54 inches

ItemPackageDimensions_Width : 20.28 inches

ItemPackageQuantity : 1

ItemTypeKeyword : science-lab-sieves

Manufacturer : WYDDDARY

NumberOfItems : 1

PartNumber : CD230362

ProductDescription :

Parameters:

Material: High quality stainless steel

Voltage: 110V

Power: 80W*2

Machine size: 39.4*16.14*(20.7-23)"

Size of feed port: 16.14*11.81"

Mesh size: 2mm

Mesh shape: Round Hole

Speed: 3000RPM

Use Maintenance

1.Before use, check all parts and accessories to ensure that the installation is correct before power.

2.The vibrating parts of the machine shall not be connected with or in contact with any object outside the machine while the machine is in operation.

3.When the material is fed, it should be fed in the direction of the whole width of the screen at the feed inlet to ensure the even distribution of the material on the screen surface.

4.When the material falls, there should be no big impact, so as not to damage the screen.

5.No retained material shall be found on the screen surface before starting or stopping the machine.

6.If there is abnormal sound during the operation of the equipment, it should be immediately shut down to check, after troubleshooting can boot.

ProductSiteLaunchDate : 2024-10-24T15:09:37.224Z

UnspscCode : 41000000