Product Information

Specification

Brand : WYDDDARY

BulletPoint : Vacuum degree is the most important process parameter for rotary evaporators, and users often encounter the problem of insufficient vacuum degree, which is often related to the properties of the solvents used. In industries such as biochemical pharmaceuticals, water, ethanol, acetic acid, ethyl ether, petroleum ether, chloroform, toluene, etc. are often used as solvents. However, general vacuum pumps cannot withstand strong organic solvents, and special corrosion-resistant vacuum pumps can be selected. (We recommend using a water circulation vacuum pump, which is available in our company).

BulletPoint1 : High Quality Material: Reasonable structure with High quality Material. Adapt high Borosilicate GG3.3 Glass ,Stainless Steel SUS304 and aluminum parts

BulletPoint2 : Seal: Using PTFE and rubber compound seal, can maintain high vacuum. Vacuum system with a vacuum gauge, the choice of low boiling point materials can choose the best working vacuum. PTFE and Rubber seal wearing parts of all the new national standard, user-friendly replacement

BulletPoint3 : Condenser: Double coil Condenser to make sure to chill effect and recycle. Between the sub-condenser and the receiving bottle with automatic switching device. Each unit is also equipped with an easy-to-use vacuum release and a continuous feed system, which allows solvent to be constantly drawn into the rotating flask without needing to stop the operation

BulletPoint4 : Specific Performance: Speed controller is stepless ,stable and reliable. Heating Water/Oil Bath with Intelligent Temperature control system. The rotating bottle is connected with nuts for easy handling

BulletPoint5 : Wide Application: Rotary evaporator is mainly used for pharmaceutical, chemical and biological pharmaceutical industries such as concentration, crystallization, drying, separation and solvent recovery

Color : Gold Color

ExternallyAssignedProductIdentifier1 : 0198462642200

ExternallyAssignedProductIdentifier2 : 198462642200

IncludedComponents : host

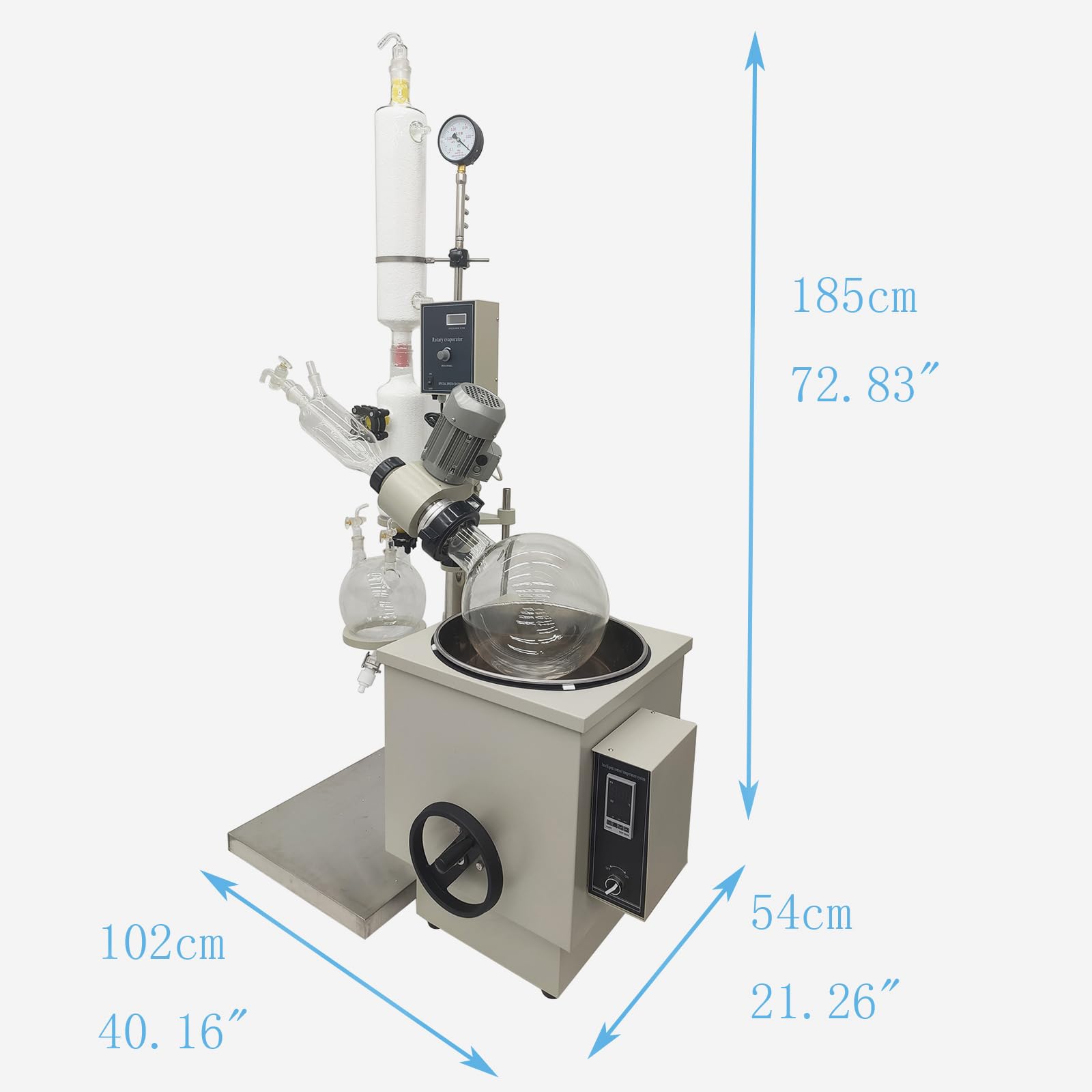

ItemName : WYDDDARY 10L Manual Lifting Rotary Evaporator with Intelligent Control Temperature System 0-120 RPM Rotation Speed Rotavapor Lab Evaporation Equipment Without Plug 5L Collect Bottle 110V

ItemPackageDimensions_Height : 35 inches

ItemPackageDimensions_Length : 43 inches

ItemPackageDimensions_Width : 31 inches

ItemPackageQuantity : 1

ItemTypeKeyword : science-lab-rotary-evaporators

Manufacturer : WYDDDARY

Material : glass

ModelName : WBTYgud52q6afe-13

ModelNumber : px201

NumberOfBoxes : 1

NumberOfItems : 1

PartNumber : CD220513

ProductDescription :

Rotary evaporator is mainly used for pharmaceutical, chemical and biological pharmaceutical industries such as concentration, crystallization, drying, separation and solvent recovery.

Working principle:

Under vacuum conditions, heat with constant temperature, make the rotating bottle rotate at constant speed, the material in the bottle surface will form a large area of film, and evaporate efficiently .

High Temperature Vapors meet condenser will chill and come back to receiving flask .Particularly suitable for high-temperature decomposition of biological products easily degeneration of concentrated purification.

Specification:

Rotating Flask (L):10L

Collecting Bottle (L):5L

Stirring Speed(RPM):0-120

Stirring Power(W):120/180

Temperature Range:0-200℃

Vacuum:-0.098

Tem. Accuracy:±1℃

Bath Power(W):3000

Supply Voltage(V):110V60Hz

Item Included:(220513)

10L Rotary Evaporator Series

ProductDescription1 : I. Purpose and Features The rotary evaporator is mainly used for concentration, crystallization, drying, separation and solvent recovery in the pharmaceutical, chemical and biopharmaceutical industries. Its principle is to heat at a constant temperature under vacuum conditions, causing the rotating bottle to rotate at a constant speed, forming a large area of film on the bottle wall for efficient evaporation. The solvent vapor is cooled by an efficient glass condenser and collected in a collection bottle, greatly improving evaporation efficiency. It is particularly suitable for the concentration and purification of biological products that are prone to decomposition and denaturation at high temperatures. The company's rotary evaporator combines the essence of similar domestic products and the company's successful experience, and has formed a series of 2L, 3L, 5L, 10L, 20L, 50L, with product design following the principles of efficiency, practicality, and economy. All for the sake of users. Characteristics of RE201D rotary evaporator 1. The use of PTFE and fluorine rubber composite seals can maintain a high degree of vacuum. 2. Adopt high-efficiency condenser to ensure high recovery rate. 3. Continuous feeding is possible. 4. Digital thermostatic control of the water bath pot. Lifting of the hand wheel of the water bath pot 5. Reasonable structure, careful materials, stainless steel and aluminum alloy parts are widely used in mechanical structure, and high temperature and high boron glass is used for all glass parts. The key components of the electrical appliances are imported. The fluorine rubber seal has been fully adopted in the new national standard, which is convenient for users to purchase and replace.

ProductDescription2 : II. Main Technical Parameters Rotating bottle capacity: 500-2000ml Capacity of collection bottle: 500-1000ml Rotating speed: 10-120 rpm (AC stepless speed regulation) Motor power: 40W Water bath pot power: 1.5KW Power supply voltage: 220V50Hz/60Hz±10% III. Instrument installation The rotary evaporator consists of three main parts: mechanical parts, glass parts, and a thermostatic water bath. The large module is packaged in a box when it leaves the factory, making installation very convenient. The specific procedure is as follows: 1. Install the pressure gauge rod on the stainless steel pole and tighten it. 2. Remove one nut at the lower end of the stainless steel frame, tighten the other nut on the stand, and thread it into the stainless steel base plate. Then tighten the nut with the removed nut, and make sure that the front of the pressure gauge faces the installer. 3. Place the rack steadily on the workbench. If it is uneven, adjust the screws inside the four hard rubber feet under the base plate. 4. Move the center of the head to a height of 48cm from the chassis, tilt it to the right by about 25 degrees, and lock the various locking screws on the frame. 5. Fix the electric control box according to the drawing and plug in the five-pin plug of the motor. 6. Fix the flange end of the four-way bottle on the head of the machine, and make the upper and lower ports of the four-way bottle vertical. 7. Insert the condenser into the upper opening of the four-way bottle, adjust the movable joints to make the condenser vertical, and use a fixing clip to hold it. The pipe joints of the condenser should be backward. 8. Insert the feeding switch into the four-way bottle, connect the collection bottle to the lower opening of the four-way bottle, secure it with a bottle clamp, and attach the rotating bottle to the right end of the rotating shaft, securing it with a bottle clamp. 9. Place the water bath pot under the rotating bottle and add clean water to 2/3 of the pot (tap water should be left for 1-2 days). 10. Connect the vacuum tube connector at the exhaust tube with a vacuum tube, and connect the other connector to the vacuum pump or laboratory vacuum switch. Precautions: (1) All glass pieces should be cleaned before installation. (2) Apply a small amount of vacuum grease to each standard port and sealing surface to increase air tightness. (3) After installation, the head position should be locked and cannot be moved.

ProductDescription3 : IV. Usage The speed of the rotary evaporator depends on three factors: The higher the vacuum degree, the faster the speed. The vacuum degree should not be less than 0.096 MPa when water evaporates. 2. The higher the temperature of the water bath, the faster the speed. Generally, it should not exceed 80℃, and the specific requirements should be followed according to the process requirements. 3. The lower the cooling water temperature, the faster the speed, and the better the effect of using refrigerated water. Second, main technical parameters Rotating bottle capacity: 500-2000ml Capacity of collecting bottle: 500-1000ml Rotating speed: 10-120 rpm (AC stepless speed regulation) Motor power: 40W Water bath pot power: 1.5KW Power supply voltage: 220V50Hz/60Hz±10% III. Instrument installation The rotary evaporator consists of three main parts: mechanical parts, glass parts, and a thermostatic water bath. The large module is packaged in a box when it leaves the factory, making installation very convenient. The specific procedure is as follows: 1. Install the pressure gauge rod on the stainless steel pole and tighten it. 2. Remove one nut at the lower end of the stainless steel frame, tighten the other nut on the stand, and thread it into the stainless steel base plate. Then tighten the nut with the removed nut, and make sure that the front of the pressure gauge faces the installer. 3. Place the rack steadily on the workbench. If it is uneven, adjust the screws inside the four hard rubber feet under the base plate. 4. Move the center of the head to a height of 48cm from the chassis, tilt it to the right by about 25 degrees, and lock the locking screws on the frame.

ProductSiteLaunchDate : 2024-08-31T03:52:13.996Z

Size : 5.5mm

Style : Without ETL Certified to UL and CSA

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

UnitCount : 1

UnspscCode : 41000000

Voltage : 110 volts