Product Information

Specification

BatteriesIncluded : 1

BatteriesRequired : 1

Brand : Futt

BulletPoint1 :

BulletPoint10 : Professional Grade Tools: Ideal for machinists, engineers, and fabricators requiring precise measurements in machining, quality control, and setup operations.

BulletPoint2 :

BulletPoint3 :

BulletPoint4 :

BulletPoint5 :

BulletPoint6 : Ultra-Precision Micrometers: Six sizes (0-6'') with 0.0001'' Vernier graduations for high-accuracy measurements. Hardened, carbide-tipped spindle for durability.

BulletPoint7 : Telescoping Gauge Set: Ranges from 5/16'' to 6'' (8.0-150.0mm), with precision-ground, hardened tool steel contact points for accurate internal measurements.

BulletPoint8 : Durable and Portable Stand: Steel micrometer stand with adjustable, lockable clamp for stable measurements. Folding design enhances portability.

BulletPoint9 : Complete Measurement Kit: Includes calibration standards and wrenches for accurate setup. Fitted wood case for micrometers and vinyl case for gauges ensure protection.

Color : 0-25mm

CustomerPackageType : Standard Packaging

ExternallyAssignedProductIdentifier : 9330191355421

ExternallyAssignedProductIdentifier1 : 0734779810040

ExternallyAssignedProductIdentifier2 : 734779810040

ExternallyAssignedProductIdentifier3 : 0603908585831

ExternallyAssignedProductIdentifier4 : 04946368673011

ExternallyAssignedProductIdentifier5 : 0603908030027

ExternallyAssignedProductIdentifier6 : 04946368015804

Hazmat1 : LITHIUM METAL BATTERIES PACKED WITH EQUIPMENT

Hazmat10 : EG_SmallLithiumMetalBatteryWithEquipment

Hazmat11 : ES_SmallLithiumMetalBatteryWithEquipment

Hazmat12 : FR_SmallLithiumMetalBatteryWithEquipment

Hazmat13 : GB_SmallLithiumMetalBatteryWithEquipment

Hazmat14 : IN_SmallLithiumMetalBatteryWithEquipment

Hazmat15 : IT_SmallLithiumMetalBatteryWithEquipment

Hazmat16 : JP_SmallLithiumMetalBatteryWithEquipment

Hazmat17 : MX_SmallLithiumMetalBatteryWithEquipment

Hazmat18 : NL_SmallLithiumMetalBatteryWithEquipment

Hazmat19 : PL_SmallLithiumMetalBatteryWithEquipment

Hazmat2 : UN3091

Hazmat20 : SA_SmallLithiumMetalBatteryWithEquipment

Hazmat21 : SE_SmallLithiumMetalBatteryWithEquipment

Hazmat22 : SG_SmallLithiumMetalBatteryWithEquipment

Hazmat23 : TR_SmallLithiumMetalBatteryWithEquipment

Hazmat24 : US_SmallLithiumMetalBatteryWithEquipment

Hazmat25 : 9

Hazmat3 : II

Hazmat4 : AE_SmallLithiumMetalBatteryWithEquipment

Hazmat5 : AU_SmallLithiumMetalBatteryWithEquipment

Hazmat6 : BR_SmallLithiumMetalBatteryWithEquipment

Hazmat7 : CA_SmallLithiumMetalBatteryWithEquipment

Hazmat8 : CN_SmallLithiumMetalBatteryWithEquipment

Hazmat9 : DE_SmallLithiumMetalBatteryWithEquipment

IncludedComponents : inc

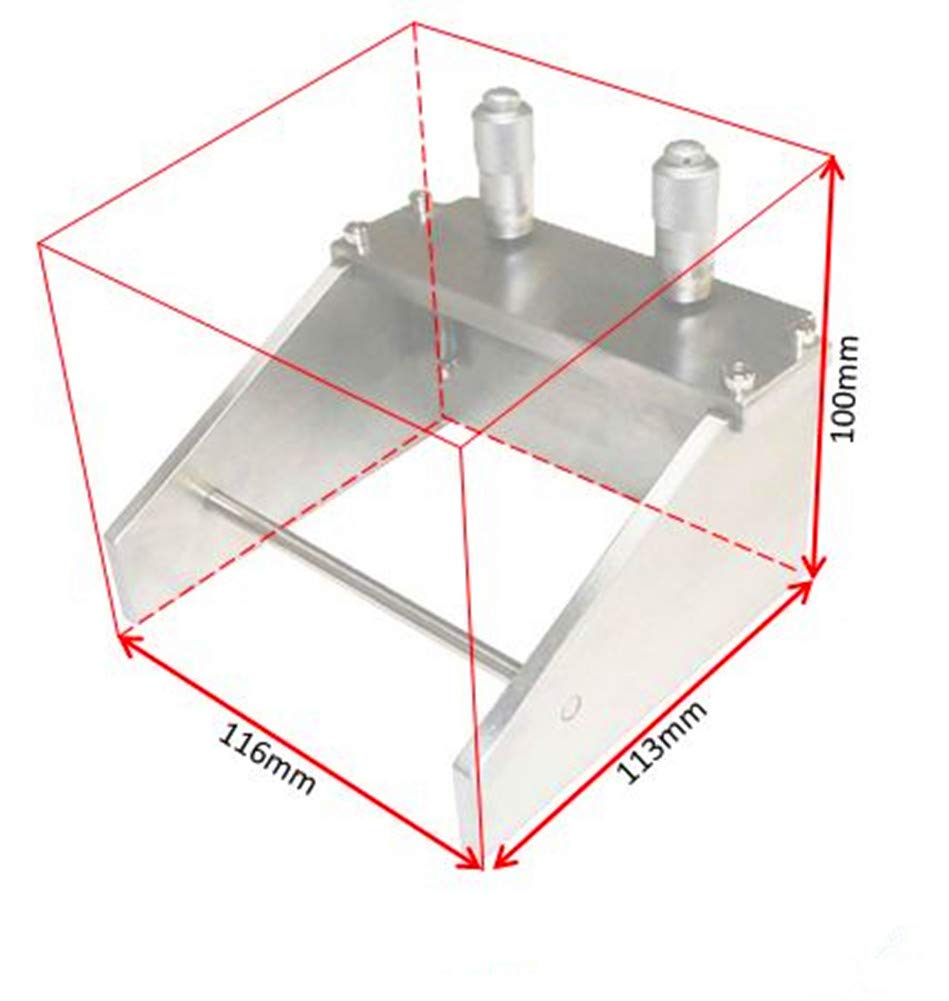

ItemName : Micrometer Adjustable Film Applicator - 100 mm Width (film casting doctor blade)

ItemPackageDimensions_Height : 13.1 centimeters

ItemPackageDimensions_Length : 2.7 centimeters

ItemPackageDimensions_Width : 5.6 centimeters

ItemPackageQuantity : 1

ItemTypeKeyword : outside-micrometers

Manufacturer : Futt

Material : Stainless steel

MeasurementAccuracy : 0.03 mm

ModelNumber : 293-333-30

NumberOfBoxes : 1

NumberOfItems : 1

NumberOfLithiumMetalCells : 1

PartNumber : 070hsigzf3xer1323

ProductDescription :

Usage method:

1. Place the coater on a completely flat test surface and adjust the clearance required by the scraper to twice the thickness of the required wet film.

2. In the front section of the coated knife, a small amount of test samples are poured between the end plates, and the instrument is moved on the surface at a slow and uniform speed of about 1-2 cm per second until the liquid has been fully coated and/or any remaining liquid has been removed from the end of the coated path.

3. The exact ratio of wet film thickness to any clearance of the coated knife depends on the material used, the viscosity and texture of the liquid, the pressure applied on the coated knife, the speed of the coated film and the geometric shape of the edge of the coated film.

4. The actual wet film should be measured by a wet film thickness gauge, and the gap should be adjusted until the required wet film thickness is reached.

Maintenance and maintenance:

1. Clean the instrument with appropriate solvents immediately after each use.

2. Both ends of the scraper move in the groove. The groove must be kept free of sample material at all times.

3. Differential heads may occasionally need to be repositioned. To correct wear or dislocation, components must be lowered or raised, which can be achieved by loosening (and removing) two hidden fixed screws on each differentiator.

It takes about 10 days for all our products to reach the designated address by DHL.

ProductSiteLaunchDate : 2018-08-17T07:00:00.000Z

Range : 1

Resolution : 0.01 mm

Size : 4 to 4.9 Inches

SupplierDeclaredDgHzRegulation : not_applicable

UnitCount : 1