Product Information

Specification

Brand : Sherline

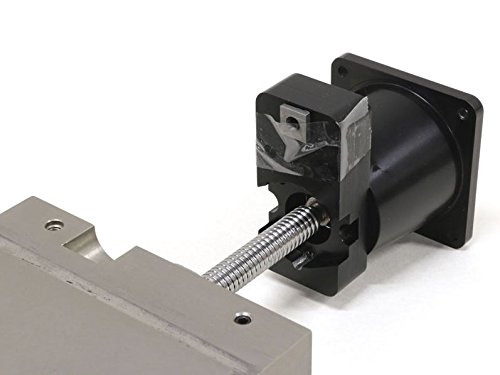

BulletPoint1 : Kit includes include ball leadscrews, stepper-motor coupling, and the ball screw mill saddle

BulletPoint2 : Ball Screw Retrofit Kit for Mill X/Y-Axes with Electroless Nickel/Teflon Plated Saddle

BulletPoint3 : 2 pieces - 4-7/8" long Cranked Boring Bars 9 pieces - 3-1/4" long Bit Variety

BulletPoint4 : Suitable for machining mild steel brass copper and plastics

BulletPoint5 : For metal lathe, mini lathe, milling other general machining operations such as turning & boring

Color : Tz20002mg

ExteriorFinish : Zinc

ExternallyAssignedProductIdentifier : 6920836688736

ExternallyAssignedProductIdentifier1 : 0713289052362

ExternallyAssignedProductIdentifier2 : 713289052362

FinishType : Brass

ItemName : Sherline 6810 Mill Ball Screw X/Y-Axes Retrofit Kit

ItemPackageDimensions_Height : 7 inches

ItemPackageDimensions_Length : 8 inches

ItemPackageDimensions_Width : 6 inches

ItemPackageQuantity : 1

ItemTypeKeyword : power-metal-lathes

Manufacturer : Sherline

Material : Aluminum

ModelNumber : CNC00154

NumberOfPieces : 1

PartNumber : sher-6810

PowerSourceType : Manual

ProductDescription : IMPORTANT: REQUIRED ORDERING INFORMATION When ordering your new Ball Screw Retrofit Kit, you will need to supply the following information for your current machine so we can ensure you receive the correct length of the ball screw for each axis: Machine Model, Mill Table Length, Mill Base Length, Mill Column Bed Length, Does your vertical milling column base have a 1/2″ through-hole for the Y-axis Brass Cover Tube?******The key upgrade parts for this ball screw retrofit kit include ball leadscrews, stepper-motor coupling, and the ball screw mill saddle (with nickel / Teflon plate). All retrofits come with the stepper-motor mount, coupling, bearings, preload nut, and ball screw fully assembled in our factory. We do not sell these parts individually for you to assemble. The ball leadscrew and the rest of the assembly are assembled and checked at the factory. We place an O-ring on the end of the ball screw, below the saddle, away from the motor mount. The O-ring is placed there to help ensure that the ball nut does not thread itself off the ball screw. If the ball nut threads off the ball screw, the balls in the ball nut will come out. At this point, the ball screw is scrap. There is no way to fix it! For this reason, the O-ring is to remain on the ball screw until the ball screw assembly is fully assembled on your machine. After you have assembled your ball screw on your machine, you may remove the O-ring. NOTE: On retrofits, the only way possible for your ball leadscrew to have excessive slop (backlash), is if some of the balls have come out of the ball nut. We will not replace ball leadscrews that have excessive slop (backlash)! Please email us the required question answers.

ProductSiteLaunchDate : 2015-08-07T07:00:00.000Z

SpecificUsesForProduct : General Purpose

Style : Modern

SupplierDeclaredDgHzRegulation : not_applicable

SurfaceRecommendation1 : Brass

SurfaceRecommendation2 : Plastic

SurfaceRecommendation3 : Metal

SurfaceRecommendation4 : Copper

UnitCount : 1