Product Information

Specification

Brand : INTSUPERMAI

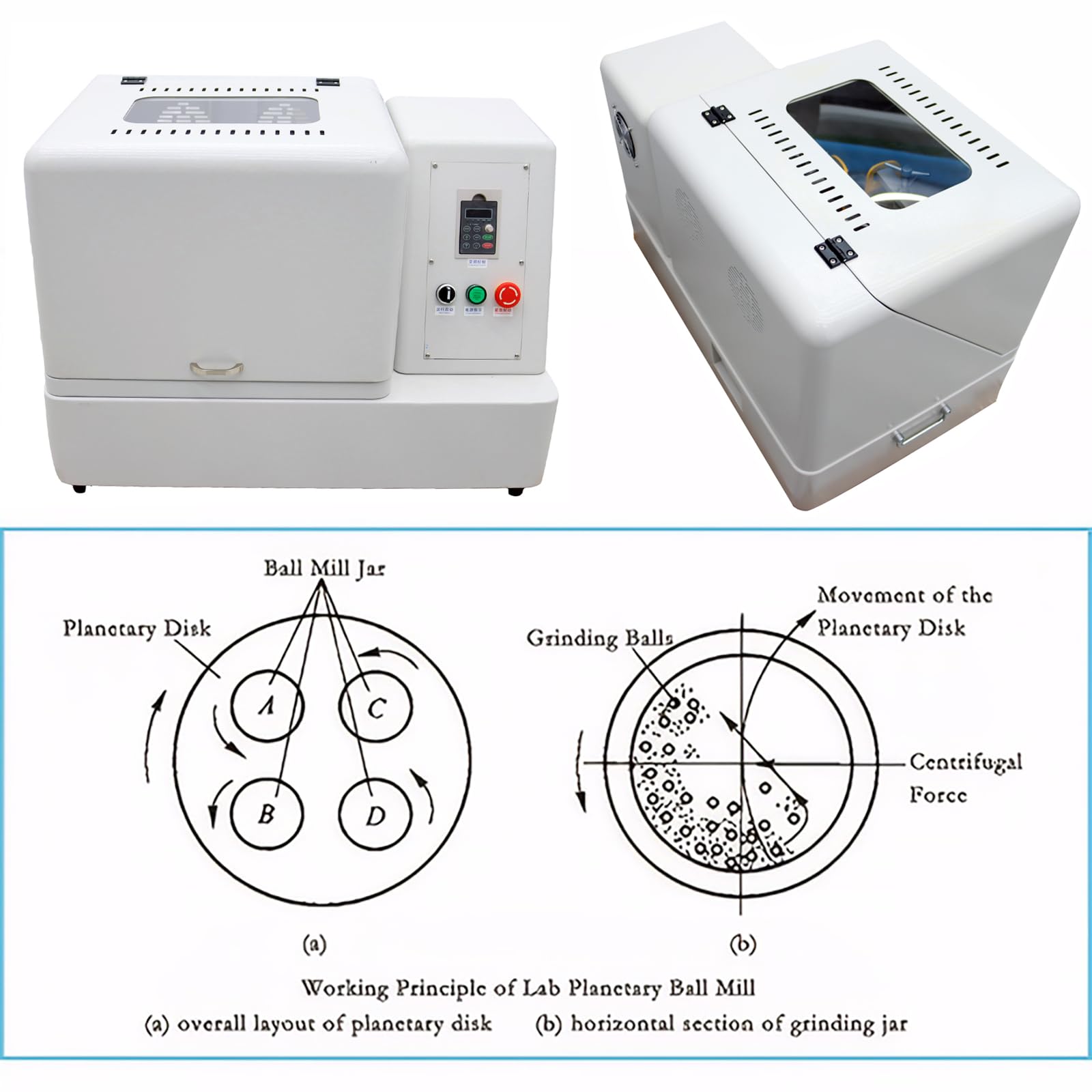

BulletPoint1 : Planetary ball mill has 4 ball grinding jar holders installed on one planetary disk. When the planetary disk rotates, the jar axis makes planetary movements and the balls in the jars grinds and mixes samples in high speed movement. The instrument can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of grinded products can be as small as 0.1 micron

BulletPoint2 : Pulverizer Ball Mill Machine has multiple grinding modes to choose. Automatic and programmable control with LED display. High Uniformity and excellent repeatability. Fast rotational speed, high efficiency and fine granularity

BulletPoint3 : Large range of materials available for grinding tools. Gear-drive offers an effective solution to problems caused by belt driving. Four samples with different sizes and materials in one experiment. Programmable interval and pause times. Stepless speed regulation, reversing function

BulletPoint4 : Low center of gravity, good rigidity, compact structure, low noise, safe and reliable operation, no pollution and small wear. Cooling of the grinding chamber with a built-in fan for long grinding times. It is the ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratories

BulletPoint5 : Planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume high-tech material production. The instrument has small volume, complete function, high efficiency and low noise. The products is extensively applied to in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc

ExternallyAssignedProductIdentifier1 : 0723508842063

ExternallyAssignedProductIdentifier2 : 723508842063

ItemForm : Granule

ItemName : INTSUPERMAI 4L Pulverizer Ball Mill Machine Ceramic Planetary Grinding Machine with 4 x 1000ml Ball Mill Grinding Jar for Laboratory Materials Grinding

ItemPackageDimensions_Height : 29 inches

ItemPackageDimensions_Length : 36 inches

ItemPackageDimensions_Width : 23 inches

ItemPackageQuantity : 1

ItemTypeKeyword : grinding-compounds

Manufacturer : INTSUPERMAI

Material : stainless steel

NumberOfItems : 1

PartNumber : SY123004

ProductDescription : Features:

Ideal for wet or dry grinding application

Automatic and programmable control with LED display.

multiple grinding modes to choose.

Fast rotational speed, high efficiency and fine granularity

Four samples with different sizes and materials in one experiment

Programmable interval and pause times

Stepless speed regulation, reversing function

Cooling of the grinding chamber with a built-in fan for long grinding times

1.1 Main Programs

1.1.1 Single direction without timing.

Samples need long or non-stop milling.

1.1.2 Single direction with timing.

Samples need to be milled in one direction for a designated amount of time before automatic shutdown.

1.1.3 Bi-direction with timing.

Samples need to run clockwise for 1.5 hours for example, then counter-clockwise for another 1.5 hours and so on, for 15 total hours, before the machine shuts down itself.

1.1.4 Single direction with paused interval and timing.

Samples need to run for 0.5 hour for example, then pause for 1 hour, then run for another 0.5 hour in the same direction and pause for another 1 hour, for 20 cycles before auto shutdown.

1.1.5 Bi-direction with paused interval and timing.

Samples need to run clockwise for 0.8 hour for example, pause for 0.5 hour, then run counter-clockwise for 0.8 hour, for 20 cycles, before auto shutdown.

Package Content:

4 pieces 1L stainless steel ball mill jar

4 pieces of sealing gasket

4 pieces of jar fastening device

5/10/15mm stainless steel mill ball: 1.8KG/3KG/1.2KG

1 piece of spare belt

1 piece of oil gun

1 piece of power plug

1 piece of brush

1 piece of user Manual

Attention: When only 2 grinding jars are used, the grinding jars must be installed diagonally to maintain the balance during the grinding process.

ProductSiteLaunchDate : 2020-11-23T07:35:07.699Z

SupplierDeclaredDgHzRegulation : unknown

UnspscCode : 27112700