Product Information

Specification

Brand : NURII

BulletPoint1 : 【Accurate Measurements 】Our digital flow meter provides precise readings with a high accuracy , ensuring reliable data

BulletPoint2 : 【Digital LCD Display】The clear LCD screen of the digital flow meter shows real-time flow rates, accumulated totals, and instantaneous flow. It makes recording your liquid usage easy.

BulletPoint3 : 【Durable Build】this digital fuel meter is designed to withstand various environments and provide long-lasting performance.

BulletPoint4 : 【MULTIPLE UNITS】The Flow Meter have a variety of units to choose: liters, gallons, pints and quarts. Your can switch easily to meet your needs.

BulletPoint5 : 【Wide Application】 LCD digital turbine flow meter built for measuring the flow rate of diesel, kerosene, gasoline etc, four different size for option caliber construction allows installation on pipeline systems or for metering purposes on fueling nozzles

Color : One Color

ExternallyAssignedProductIdentifier : 7613045798004

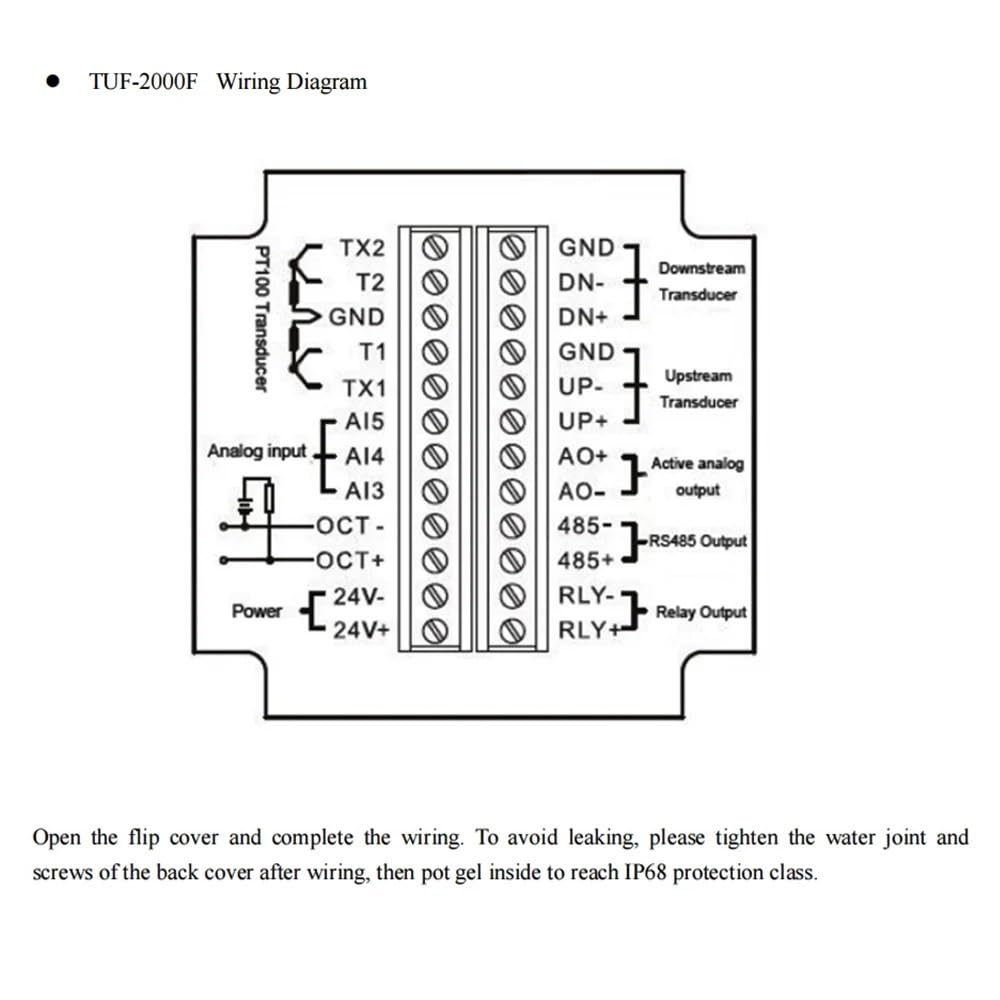

ItemName : TUF-2000F, Pipeline Flowmeter Flange Sensor, with Modbus RS485, Used for Metal Or Plastic Pipe(DN40-80mm)(DN40 (1.5 inches))

ItemPackageDimensions_Height : 1 centimeters

ItemPackageDimensions_Length : 3 centimeters

ItemPackageDimensions_Width : 2 centimeters

ItemPackageQuantity : 1

ItemTypeKeyword : science-lab-flowmeters

Manufacturer : NURII

ModelNumber : NURII

NumberOfBoxes : 1

NumberOfItems : 1

PartNumber : NURII

ProductDescription : TUF-2000F Pipeline Ultrasonic Flowmeter Flange Sensor With Modbus RS485 Used For Metal Or Plastic Pipe(DN40-80mm)

Introduction:The ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed conduit. The flow meter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers.

Requirements for pipeline installation:

Try to meet the requirements of the straight pipe section, at least 10 times the pipe diameter from the upstream elbow and 5 times the downstream pipe diameter. When not satisfied, install the sensor as close as possible to the lower part of the middle.

If there is an insulation layer outside the pipe, remove part of the insulation layer according to the installation distance and installation mode, and ensure that the two sensors are on the same axis section after positioning, and the sensor must be installed on the side of the pipe.

Metal pipe needs to be polished, use angle grinder or straight plate file in the installation point to grind out a square of about 1.5 times the area of the bottom of the sensor (PVC tube does not need grinding, wipe clean) after polishing requirements: bright, non-corrugated, no rust point.

==========

Hign-concerned Chemical : None

Measurement Range : 0.03m/s-10m/s

Model Number : TUF-2000F

DIY Supplies : Plumbing

Origin : Mainland China

Pipe material : Carbon steel, Stainless steel, PVC, etc.

Sensor : DN40~DN1000(optional),-30~160

Power supply : DC24V

ProductSiteLaunchDate : 2024-08-05T07:32:48.749Z

Size : DN40 (1.5 inches)

UnitCount : 1