Product Information

Specification

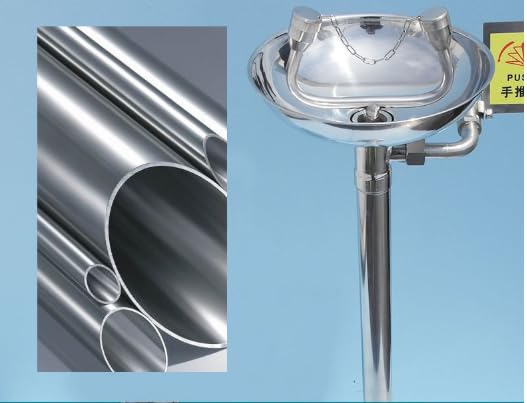

BaseType : Pedestal

Brand : cjc

BulletPoint1 : 【Dual Spray Hands-Free Operation】 Self-retracting dust covers automatically open during activation, triggering continuous 0.8 GPM flow from both spray heads. Maintains water delivery without manual intervention for emergency eye irrigation.

BulletPoint2 : 【Industrial 304 Stainless Steel】Corrosion-resistant construction withstands chemicals, humidity, and frequent sanitation. 11.8” basin contains water effectively while textured floor base prevents slips in wet environments.

BulletPoint3 : 【Instant-Access Manual Control】Pull the vertical activation rod to start flushing immediately. Locks in "on" position for continuous 15+ minute flow—no need to hold controls during critical eye rinsing.

BulletPoint4 : 【High-Visibility Emergency Ready】 Bright yellow safety labels and reflective decals ensure rapid identification in low-light conditions. Ideal for labs, factories, and workshops requiring urgent eye care.

BulletPoint5 : 【Plumbed & Low Maintenance】 Pre-assembled unit connects to 1/2” water lines. Built-in sediment filters and tool-free nozzle access simplify weekly flow tests to ensure system readiness.

Color : Sliver

ExternallyAssignedProductIdentifier : 8719623562575

FinishType : Polished

ItemName : Eye Wash Station, Pedestal Mounted Eyewash Station Stainless Steel Eye Washing Station Adjustable Water Flow Hands Free Operation Eye Wash Units with Dual Spray Heads

ItemTypeKeyword : industrial-and-scientific-eye-wash-units

Manufacturer : cjc

ModelName : 1

ModelNumber : 1

NumberOfItems : 1

PartNumber : 1

ProductDescription :

Rapid-Response Eye Care for Hazard-Prone Environments

This stainless steel pedestal eyewash station delivers critical eye decontamination capabilities for laboratories, industrial sites, and manufacturing facilities. Designed for instant activation and continuous flow, it prioritizes safety without complex controls.

Key Features & Benefits

✅ Continuous Hands-Free Flushing:

Once activated via the vertical pull rod, the system provides uninterrupted 0.8 GPM flow (0.4 GPM per spray head) to both eyes. Dual aerated streams gently rinse away chemicals or particulates.

✅ Hygienic Auto-Open Nozzles:

Self-cleaning dust covers retract automatically upon activation, preventing debris buildup. 304 stainless steel nozzles resist mineral deposits for consistent performance.

✅ Industrial Durability:

Rust-proof 304 stainless steel construction survives harsh environments—from chemical plants to outdoor construction sites. Wide 11.8” basin minimizes splashback during use.

Technical Specifications

Material: 304 stainless steel (basin, frame, nozzles)

Flow Rate: 0.8 GPM (15+ minute runtime)

Water Supply: 1/2” NPT connection (tempered water recommended)

Dimensions: 33” H x 12” basin diameter

Ideal For:

Acid/alkali handling facilities

Pharmaceutical cleanrooms

Metal fabrication workshops

University chemistry labs

Setup & Maintenance

1. Professional Installation: Connect to potable water lines. Ensure water temperature stays between 16–38°C for user comfort.

2. Weekly Testing: Flush system for 3 minutes to prevent stagnation.

3. Annual Service: Inspect valves and replace filters as needed.

Safety Enhancements

Latching Activation Rod: Maintains water flow without constant pressure.

Non-Slip Base: Textured pedestal prevents movement during emergencies.

High-Contrast Markings: Yellow/black labels enhance visibility in emergencies.

ProductSiteLaunchDate : 2025-05-09T03:05:09.674Z

SupplierDeclaredDgHzRegulation : not_applicable

SupplierDeclaredHasProductIdentifierExemption : 1

UnspscCode : 46181800