Product Information

Specification

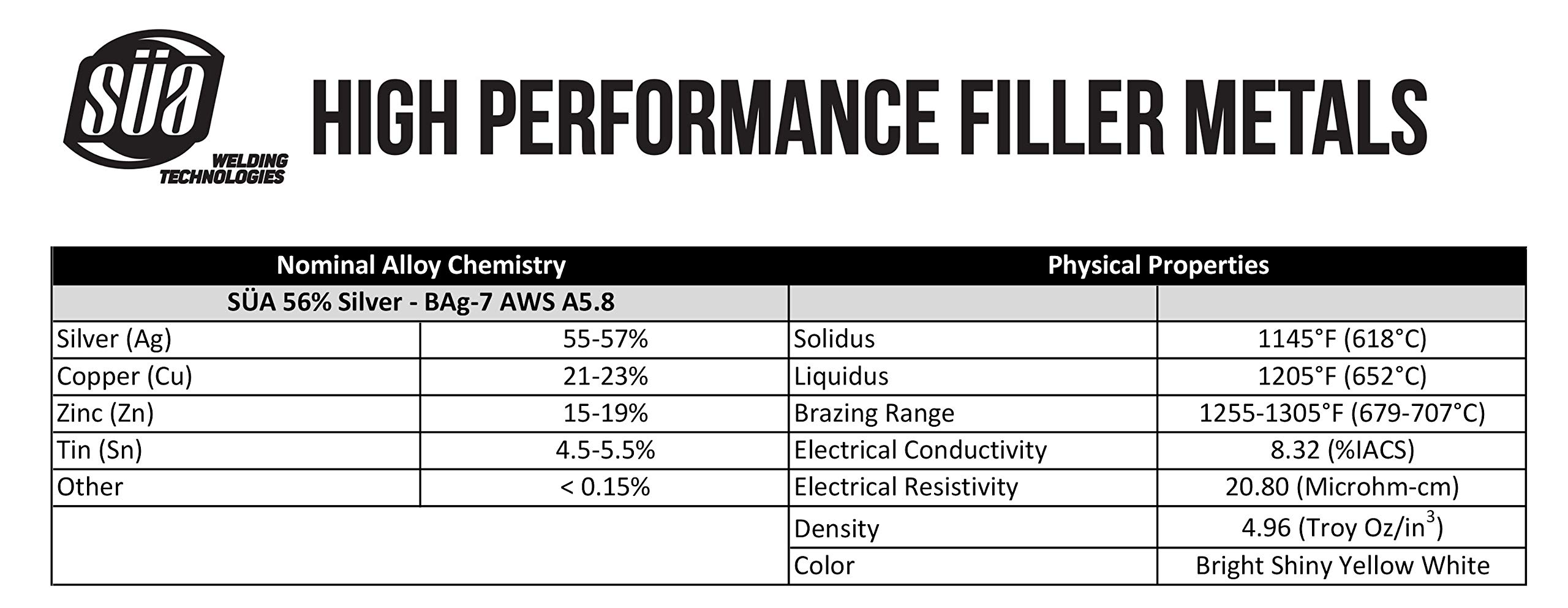

Brand : SÜA

BulletPoint1 : SÜA 56% Silver is the lowest melting temperature high silver brazing filler metal, it is a cadmium-free alloy with a narrow melting point range. This alloy offers good fluidity and joint strength and is used to braze ferrous and non-ferrous alloys in joints requiring a low temperature like copper, brass, steel, stainless steel and some nickel alloys.

BulletPoint2 : Complies with ANSI/AWS A5.8 BAg-7, ASME SFA 5.8, & QQ-B-654A Class BAg-7, AMS 4763, National Sanitation Foundation Standard 51, ISO 17672 Ag 156

BulletPoint3 : The silver deposit color is a good match on stainless steel. Its excellent fluidity promotes braze penetration. Close tolerances are recommended; 0.002 – 0.005” for best performance.

BulletPoint4 : Diameter of Rod: 1/16” - Length of each Rod: 18" - Weight of each Rod: 0.25 TOz - Available in 3, 5 and 9 Rods Packages. Select your option from the menu.

BulletPoint5 : This kit includes a 6.5 Oz jar of our top-quality SÜA Silver-Flux #1 with a convenient brush attached to the cap for an easier flux application.

ExternallyAssignedProductIdentifier : 00840338557018

ExternallyAssignedProductIdentifier1 : 0784172852628

ExternallyAssignedProductIdentifier2 : 784172852628

IncludedComponents : 1

ItemDisplayWeight : 8 ounces

ItemName : SÜA® - Silver Brazing Solder Rod - Bare - 56% Ag - AWS BAg-7 - Size: 1/16" x 18" - (3 Sticks) + 6.5 Oz Flux

ItemPackageDimensions_Height : 1 inches

ItemPackageDimensions_Length : 1 inches

ItemPackageDimensions_Width : 1 inches

ItemPackageQuantity : 1

ItemTypeKeyword : brazing-rods

Manufacturer : Mundaka Technologies Inc

Material : Silver

Material1 : Aluminum

Material2 : Copper

ModelName : 99088

ModelNumber : 482731

NumberOfItems : 1

PartNumber : SWT-BAg-7_3R-F

ProductDescription : * Remove any oil, grease, or other contaminants from the surface to be brazed. * Apply flux to joint by dipping, swabbing or brushing area being brazed. The flux may be used as supplied or diluted. * Apply heat, by torch, induction or other means to area being brazed after flux has been applied to activate the flux. * Feed the braze alloy into the joint, unless a brazing preform is already in place. * Clean flux residues from brazed joint using hot water (60°C ± 5°C / 140°F ± 10°F) for best results. If unavailable, room temperature water may also be used. WARNING: PROTECT yourself and others. Read and understand this information. FUMES AND GASES can be hazardous to your health. HEAT RAYS, (infrared radiation) from flame or hot metal can injure eyes. Before use, read and understand the manufacturer’s instructions, Material Safety Data Sheets (MSDS), and your employer's safety practices. Keep your head out of fumes. Use enough ventilation, exhaust at the flame, or heat source, to keep fumes and gases from your breathing zone and the general area. Wear correct eye, ear, and body protection. See American National Standard Z49.1, Safety in Welding, Cutting, and Allied Processes, published by the American Welding Society, 8669 Doral Blvd., Doral, Florida 33166; OSHA Safety and Health Standards, available from the U.S. Government Office, Washington, DC 20402.

ProductSiteLaunchDate : 2022-11-14T16:11:22.686Z

Size : 3 Rods

Speed : 900 rpm

SupplierDeclaredDgHzRegulation : not_applicable

UnitCount : 1